In terms of its terroir, this Normandy cheese is a cousin of Camembert, another cheese from the same region. Its yellow-orange rind smells strongly of hay and a barn. How is it made? We head to the dairy E. Graindorge in Livarot to find out more.

I am greeted in the dairy's boutique and treated to an incredibly visual appetizer! The entire family of Normandy cheese is on display in the store's refrigerated case. Each one is still in its original box, which all feature labels depicting the region's beautiful countryside. Four sizes of Pont-l'Evêque are available, ranging from the smallest (6 oz) to the largest (3 lbs)! For a bit of backstory, this cheese was first made in a round format by Cistercian monks living in Pays d'Auge in the 12th century. It was long referred to as "Angelot" and used as currency during fairs in Normandy. In the 18th century, the cheese started to be made in a square shape to easily distinguish it from Livarot and Camembert, two other types of cheese. In the 19th century, it became known as a luxury cheese in Paris. I can't wait to learn more about how this famous cheese is made!

Raw milk for starters

Raw milk from Chesnaye Farm was delivered to the dairy yesterday morning. It was first analyzed in the laboratory to verify its quality. The milk, which is set aside to produce exceptional PDO (Protected Destination of Origin) cheese in Normandy, is handled without heating it above 104 °F, which means an exacting set of sanitation conditions must be met. The milk gets the green light. This morning, it is being sent to the Pont-l'Evêque production line.

Raw milk is handled without heating it above 104 °F, which means an exacting set of sanitation conditions must be met.

Welcome to the dairy of the future…

We start the tour by getting dressed in the factory locker room. After putting on a white coat, cap, and shoe covers, I step inside the production room. This plant makes traditional cheese using cutting-edge technology. The air is hot (82 °F) and set to 90% humidity. The noise inside the room is deafening. At the start of the production chain, liquid rennet is poured into a series of moving carts filled with milk. You can't have cheese without rennet! The first machine on the line mixes the milk and rennet together to help with the coagulation process.

As the carts move down the line, the curds are regularly cut into smaller pieces by metal arms, then slowly mixed at several points along the process to maintain the suspension. "The curds can't become overly saturated, or they will create cheese that is too runny," says our guide, Cécile Le Martel.

A key step

Using a hopper, the curds are then compressed twice to make sure all excess water has been removed.

Now it's time for the key step. The workers take care to fill the cheese molds evenly, pressing the curds down with quick, repetitive motions. It is this step that determines the cheese's end quality, including its final weight, even consistency, and more. After they been filled, the molds are turned three times by a machine, set onto cheese racks to dry, and placed on a cart by another machine. It takes about 45 minutes for the milk to travel the full length of the production line. Ingrid's cow's milk has started its transformation into cheese.

We leave the noisy machines to follow the carts into the drying room, where the cheese will drain throughout the night. Tomorrow, they will be taken out of their molds, dipped in a salt bath, then left to dry in a curing room, a ventilated room designed to help ripen the cheese. The next step is to label the cheeses. These labels will ensure the product's traceability from the factory to our plates, which are sometimes on the other end of the world!

The secret of Pont-l'Evêque

While it's drying in the curing room, the Pont-l'Evêque is "basted" once, or sprayed down by hand with a mixture of water and enzymes. This process is what gives the cheese its straw-yellow rind.

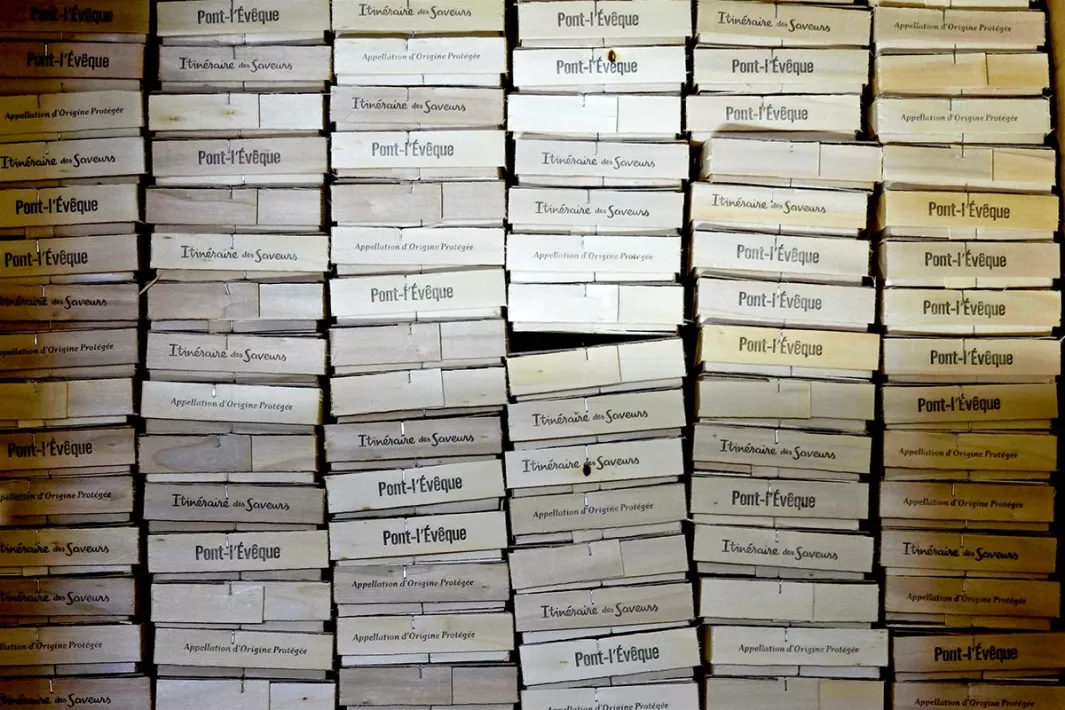

During the 21 days of ripening required by the cheese's PDO certification, the Pont-l'Evêque is turned almost every day. Once it weighs 7-8 ounces, it is tested one last time for any flaws in its shape and density. The cheese is wrapped in a special paper and placed in boxes, where it will finish ripening in transport and while waiting on the retailer's shelves. Even the boxes are made in the region using wood often sourced from local poplar groves. This cheese is "Made in Normandy," through and through!

Everyone also likes it because it is made with such art that, whether young or old, it is but cream.

Back in the store, it's time for our taste test. Don't be put off by the strong hay-and-barn smell that emanates from the cheese even before it is unwrapped from its packaging. The lightly colored, yellowish-orange rind is smooth to the touch. After it is cut diagonally, the square-shaped cheese reveals its soft and creamy center, which is dotted with small pockets of air. You can eat it without the rind to better appreciate its creaminess. The moment of truth. I put a triangle of the cheese on a slice of crusty country-style bread. The flavors are incredibly subtle—especially compared to its smell! The cheese is creamy and features a delicious note of butter and hazelnut.

I'm an instant fan.

Cooking with Pont-l'Evêque

> Interested to learn more about French cheese? Check out our Beginner's Guide To French Cheese!

Contributor

Editor